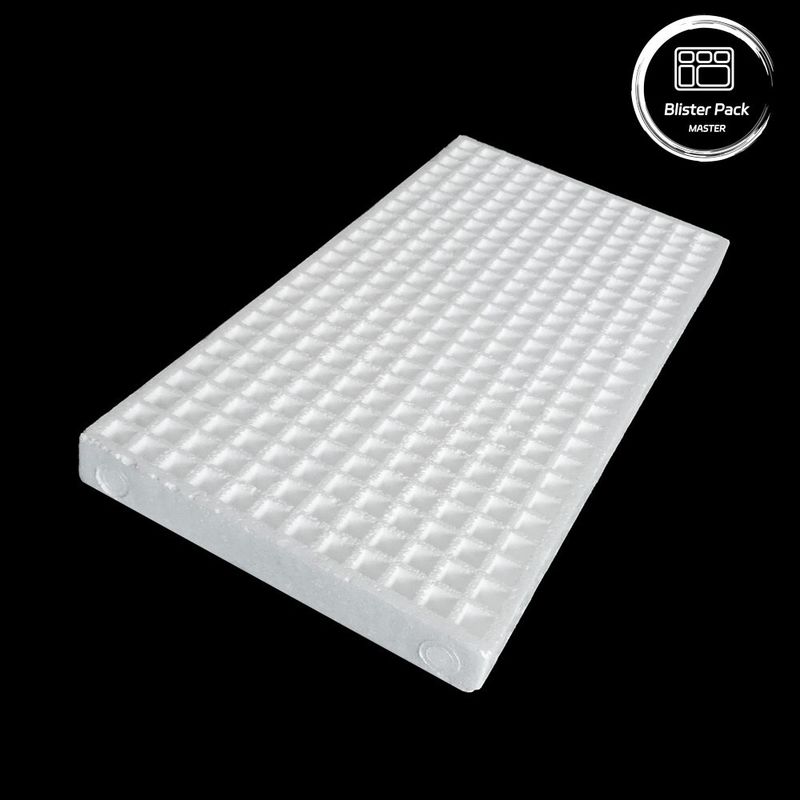

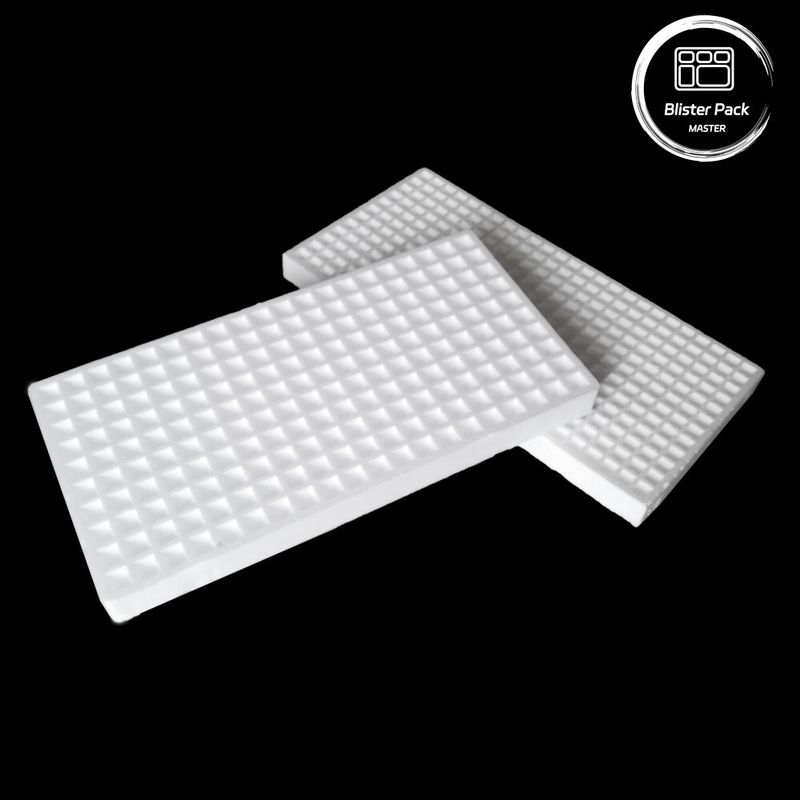

160 Holes Floating Foam Board Floating Tray - Blister Pack Master

Product Description:

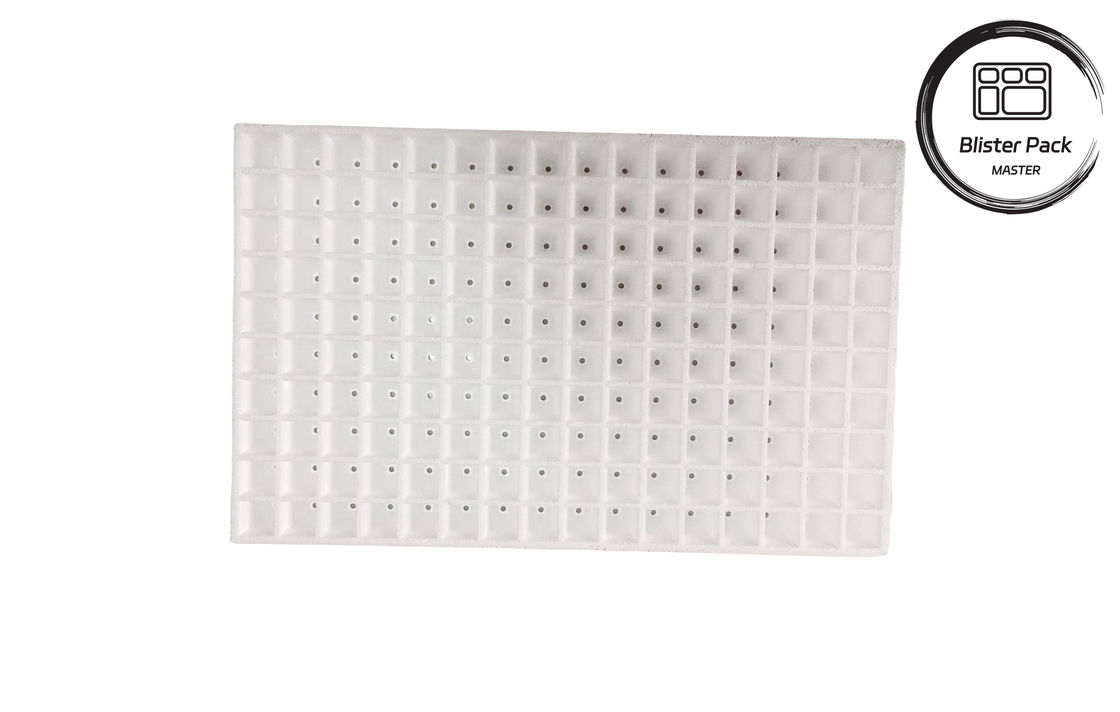

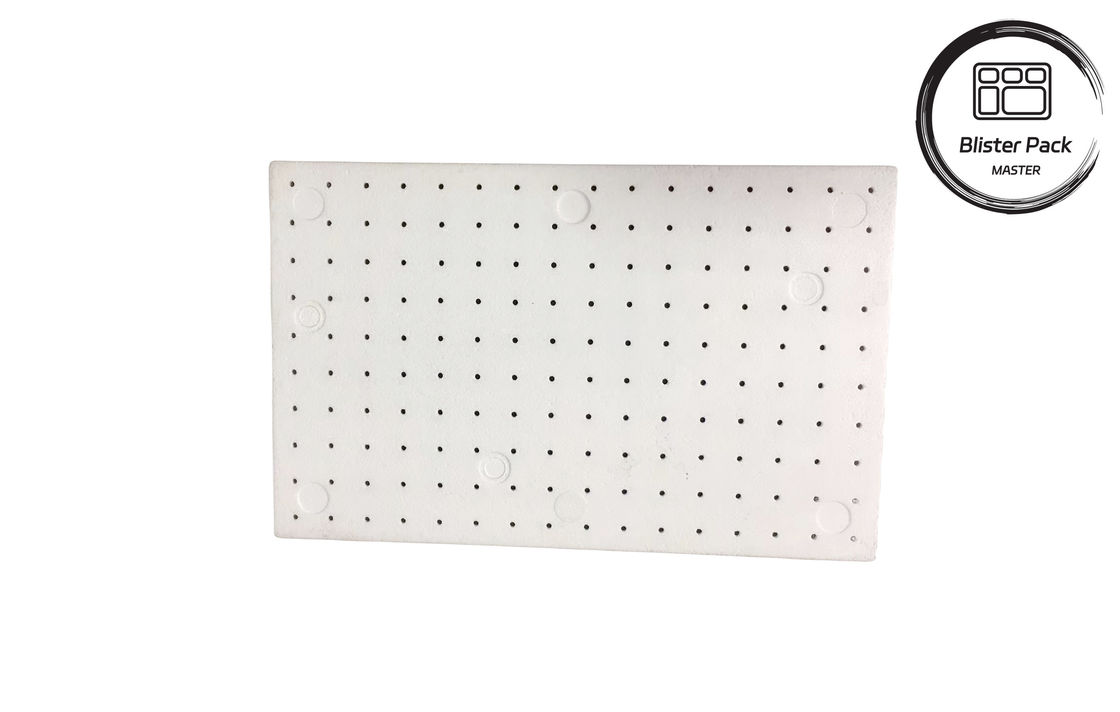

The Blister Pack Master 160 Holes Floating Foam Board Floating Tray is an innovative solution for hydroponic growing. Designed with 160 individual holes, this floating foam board is perfect for cultivating seedlings and young plants in a water-based environment. Made from high-quality foam, this tray is lightweight and buoyant, ensuring that it remains afloat while providing the necessary support for growing plants.

Ideal for use in laboratories, greenhouses, and hydroponic setups, this tray facilitates optimal growth conditions by ensuring consistent moisture and nutrient availability. Its design is particularly suited for growing vegetables, fruits, and other hydroponic crops, making it a versatile tool for modern cultivation practices.

Product Specifications:

|

Attribute

|

Specification

|

|

Usage

|

Hydroponic systems, laboratories, greenhouses, indoor gardening

|

|

Feature

|

Floating design, lightweight, supports hydroponic growing

|

|

Lead time

|

1~7 days

|

|

Customized logo available

|

Available

|

|

Dimension

|

Depends on specific product

|

|

Lead time and quantities negotiable

|

1-500: 7 days

|

|

501-10000:15 days

|

|

>10000: Lead time to be negotiated

|

|

Samples

|

Available upon request, contact sales for details

|

Notices:

- Clean the tray regularly to prevent algae and mold growth.

- Ensure proper nutrient management in the water to support plant health.

- Store in a dry place when not in use to maintain foam integrity.

Applications:

The Blister Pack Master 160 Holes Floating Foam Board Floating Tray is perfect for hydroponic growers seeking a reliable and efficient method to start and grow their plants. Its innovative design ensures plants receive the necessary moisture and nutrients directly from the water, promoting vigorous and healthy growth.

Why Choose Blister Pack Master?

- Proven Expertise: With over 15 years of specialized experience, we offer high-quality blister packaging solutions.

- Cutting-Edge Technology: We use the latest thermoforming and cutting technologies to ensure precision and efficiency in our processes.

- Tailored Customization: We provide fully customized packaging solutions, from design to materials, to meet your specific needs.

- Sustainability Commitment: Our commitment to sustainability is evident as we prioritize eco-friendly materials and processes to minimize our environmental impact.

- Superior Customer Service: Our personalized service ensures that your packaging is perfectly aligned with your brand and meets your expectations.

- Certified Quality: We are ISO9001 and ISO14001 certified, which validates our high standards of operational excellence.

Frequently Asked Questions:

Q1:What industries commonly use blister packaging?

Blister packaging is widely used across various industries including pharmaceuticals, cosmetics, electronics, and food due to its versatility and protective qualities.

Q2 Can I order a sample to test and check the quality?

Yes, we offer sample orders for you to evaluate the product quality.

Q3: What is the lead time for sample preparation and mass production?

Sample preparation typically takes 3-5 days, and mass production requires 10-15 working days.

Q4: Is there a minimum order quantity (MOQ) for the meal set?

Yes, we have a reasonable MOQ based on your requirements; please consult with our customer service for details.

Q5: How do you ship the goods, and how long does it take for them to arrive?

We ship via reliable logistics partners, and goods generally arrive within 25-30 days.

Q6: What are the design options for blister packaging?

Design options range from simple rectangular blisters to complex shapes with logo embossing, high-visibility clear windows, and multi-product cavities for promotional use.

Q7: Do you offer design assistance for blister packaging?

Yes, We offer full design support for your blister packaging, ensuring it aligns with your product requirements and brand style. Our team collaborates with you from concept creation to the final productdesign, providing:

- Expert Consultation: Understand your requirements and propose innovative solutions.

- Custom Design: Tailor designs to your product's specific dimensions and branding needs.

- Prototype Testing: Ensure the design is practical and meets all functional requirements before full-scale production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!